- Тип техники

- Бренд

Просмотр инструкции кондиционера Daikin JEHSCU-CM1, страница 7

O-CU06-DEC14-1

All specifications are subjected to change by the manufacturer without prior notice. The English te x t is the

original instruction. Other languages are the translations of the original instructions.

7

3.10 Commissioning of the Condensing Unit

Please make sure that all manual service valves are fully

open when starting the system for the first time. This

includes external and int ernal shut off valves as well as

liquid recei ver valve in the unit.

The ball valve open position is shown as below:

3.11 Compressor electrical wiring

Verificat i on of proper rotati on di rection is made by observing

that suction press ure drops and discharge pressure rises

when the compressor is energized. Reverse rotation of a

scroll compressor also results in substantially reduced

current draw. Suction tem perature will be high, discharge

temperature will be l ow and the compressor may generate

abnormal noise.

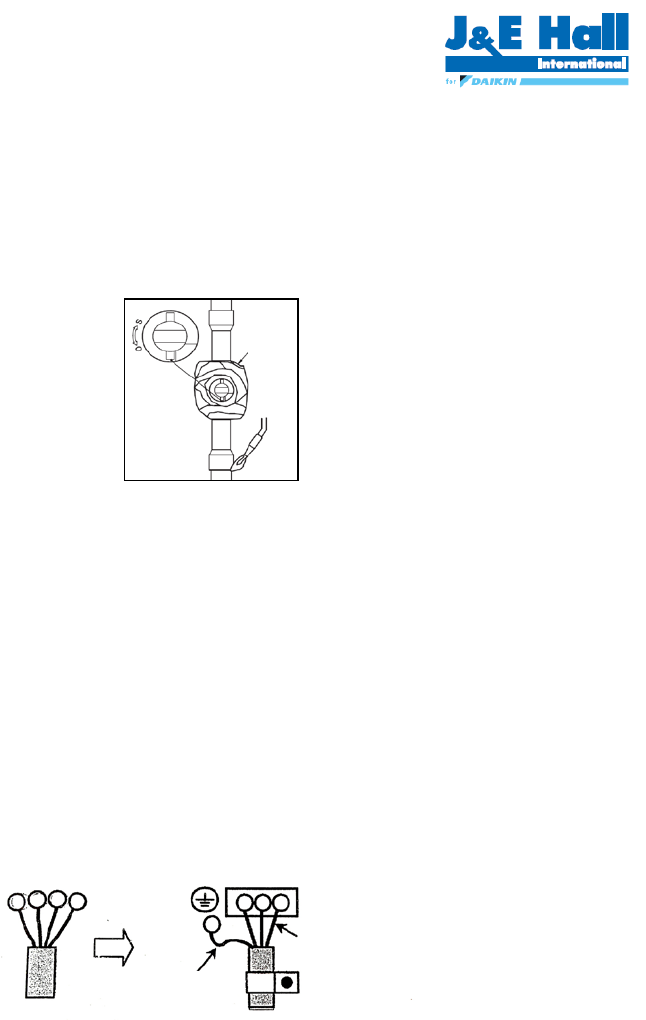

3.12 Earthing of Condensing Uni t

Installat i on of earth wire must be made to earthing screw

(labelled with earth label ) before connecting the live wires.

The earth wire shall be slack as shown in below diagram.

4. Decommissioni ng &

Disposal

At the end of the unit’s useful life, a suitably qualifi ed

engineer should decommission it. The refrigerant and

compressor oil are classed as hazardous waste and as such

must be reclaimed and disposed of in the correct manner,

including com pl etion of waste transfer paperwork. The unit

components must be disposed of or recycled as appropriate

in the correct manner.

5. Checklist

• Ensure the high low pressure controls are configured

properly.

• Ensure crankcas e heater is energized minim um 12

hours prior to start up and permanently energized.

• Check the refrigerant is correct f or intended use.

• Check all electrical c onnect i ons.

• Check all electrical terminat i on and ci rcuits are correct.

• Check compressor oil level via compressor sight glass,

the oil level should not be lower than quarter of sight

glass.

• Check the TXV capacity sizing based on indoor unit

capacity. Check TXV applic able refrigerant. Check

positi on and condition of the sensing bulb fixing

• Observed the system pressures during the charging

and initial operati on process.

• Ensure that suction pressure will decrease, disc harge

pressure will increas e. No abnormal nois e from the

compressor.

• Continue to charge the system until sight glass is clear.

Make sure that high pressure is > 14 barg for R404A

and > 8 barg for R134a when doing this charge

adjustm ent operati on. Continuous flow of clear

refrigerant t hrough t he sight glass, with perhaps an

occasional bubbl e at very high temperat ure indic ates

the refrigerant is at optim um.

• Check the compressor’s discharge and suction

pressure, to ensure it is within operating range.

Discharge temperat ure should be within 50 to 90 °C

and pressure should be around 15 to 26 barg (for

system charged with R404A) and 8 to 16 barg (for

system charged with R134a).

• Check the current of condensing unit and ensure it is

below the motor circuit breaker setti ng value.

• Check condenser fan, ensure warm air blowing off the

condenser coil.

• Check evaporator blower, ens ure it’s discharging cool

air.

• Check suction superheat and adjust expansion valve to

prevent liquid flood back to the compressor.

Recommended 5 to 20 K of suction superheat.

• Do not leave the system unattended until the system

has reached its normal operating conditi on and the oil

charge has properly adjust ed itself to maintai n the

proper level in the sight glass.

• Check periodical l y the compressor performanc e and all

the moving components during the first day of

operation.

• Check the liquid line sight glass and expansion valve

operation. If there is an indic ation that the system is low

on refrigerant, thoroughly check the syst em for leaks

before adding refrigerant.

MAX

150°C

OPEN

position

Eart wire

(

Slack)

Power supply wire

Clamp

Earth

terminal

Ваш отзыв будет первым