- Тип техники

- Бренд

Просмотр инструкции кондиционера Daikin JEHSCU-CM1, страница 3

O-CU06-DEC14-1

All specifications are subjected to change by the manufacturer without prior notice. The English text is the

original instruction. Other languages are the translations of the original instructions.

3

3. Installa ti on & Comm iss ioning

3.1 Unit site location

• In order to achieve maximum cooling capacity, the

installation location for condensing unit should be

carefully selected.

• Install the condensi ng unit in such a way so that hot air

distri buted by the condensing unit cannot be drawn in

again (as in the case of short circuit of hot discharge

air). Allow suffic i ent space for maintenance around the

unit.

• Ensure that there is no obstruction of air flow into or out

of the unit. Remove obstacles which block air intak e or

discharge.

• The location must be well ventilated, so the unit can

draw in and distribute plenty of air thus lowering the

condensing temperature.

• To optimize the unit running conditions, t he condens er

coil must be cleaned at regular intervals.

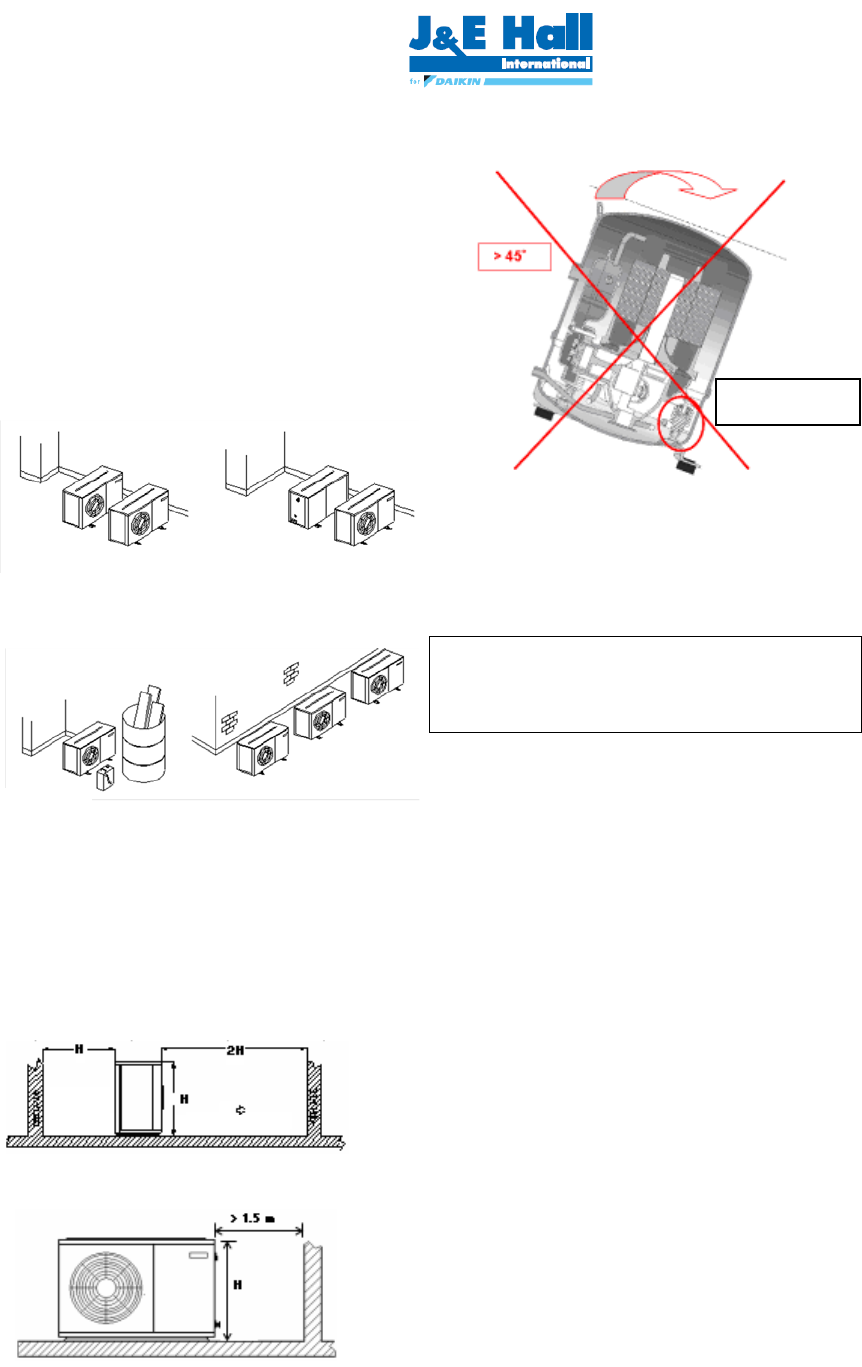

3.2 Installation Clearan ce

• The installation l ocat i on should allow suffici ent s pace

for air flow and maintenance around the unit.

• To allow sufficient space for doing servic e or

installation.

3.3 Compressor handling

To ensure compressor reliabili ty, the condensing unit and

the compressor must not be tilt greater than an angle of 45°.

Otherwise, the compressor c an fall from its 3 compressor

housing spring, which results in noisy vibrati ons during

operation and possibl e to breakdown.

3.4 Field Piping

To ensure satisfactory operati on and performance, the

following points s houl d be noted for field piping

arrangements,

• Couples one indoor unit with one outdoor condens i ng

unit only.

• Release all the pre-charged nitrogen before pi pework

connection.

• Connecting pipe si ze for suction and liquid li ne must

same as attaches to the condensing unit. Correct line

sizing will minim i ze the pressure drop and maintai n

sufficient gas velocit y for proper oil return.

• Pipework routes must be as simple and as short as

possibl e. Avoid low points on pipework where oil can

accumulate.

• Use only clean, dehydrated refrigeration grade c opper

tube with large radius elbows. The piping shall be kept

with enough bending radius.

• Braze without over filling t o ensure there is no excess

solder int o the tube.

• To prevent oxidation, blow nitrogen t hrough pi pework

when brazing.

• Install i nsulation on all sucti on lines after press ure test.

• Adequately support al l pipe work at a maximum of 2

meter intervals.

• For the condition where the outdoor condensing unit is

above the indoor unit, the height differenc e between

units shall be less than 25 m and install oil trap on

suction pipe every 4 m height. The suction pipe must

always be fitted with U-trap at the bottom.

• For the condition where the outdoor condensing unit is

below the indoor unit, the height diff erence between

units shall be less than 4 m. Pipe trap shall be install ed

upward on outlet of indoor unit (suction pipe).

• The recommended piping length is 25 m or less.

• Additional oil might be required in case field piping is

long or with many oil traps. Check the oil level of the

Important No te

Line sizing should only be determined by qualified

personnel. All local codes of practice must be observed

in the installation of refri gerant pi ping

Wrong !

Correct !

Wrong !

Correct !

Air inlet

Air Discharge

Springs to

absorb vibrations

Ваш отзыв будет первым