- Тип техники

- Бренд

Просмотр инструкции кондиционера Daikin JEHSCU-CM3, страница 8

O-CU06-DEC14-1

All specifications are subjected to change by the manufacturer without prior notice. The English te x t is the

original instruction. Other languages are the translations of the original instructions.

8

6. Service and Maintenance

The condensing units are designed to gi ve long life

operation with minimum maint enance. However, they shoul d

be routinely checked and the following service schedule is

recommended under normal circ umstanc es:

The removal of the top, side and front panels ensures that all

parts are accessible.

1. Compressor – Inspect at regular intervals

• Check for refrigerant leaks on all joints and fittings.

• Ensure that no abnormal noise or vibration is

detected during test run.

• Check the compressor oil levels and top up if

required. The oil level should not be lower than

quarter of the compressor oil sight glass. Not

applicable to AE/AJ compressor.

2. Condenser Coil – Clean and inspect at regular intervals

• Remove surface dirt, leaves, f i bers, etc. with a

vacuum cleaner (preferably with a brush or other

soft attachment rather t han a metal tube),

compressed air blown from the inside out, and/or

a soft bristle (not wire!) brus h. Do not impact or

scrape the coil with the vacuum tube, air nozzle,

etc. It may be beneficial to blow or vacuum out the

rinse water from MCHE to speed drying and

prevent pooling.

3. Power Supply – Inspect at regular intervals

• Check the running current and voltage for the

condensing unit.

• Check the electrical wiring and tighten t he wires

onto the terminal blocks if necessary.

Under normal circumst ances:

• Clean condenser coil every three months

• To assure no leakage

• Check and verify operation of all safety devic es

every three months, ensure crankcas e heater is

operational

• Check sight glass and operating conditi ons

• Check security of compressor mountings and the

bolts that hold down the unit each year

7. F-Gas Information

• From 1/1/2015, a new F-Gas Regulation (EU) No

517/2014 comes into force repealing Regulation

(EC) No 842/2006. This will affe ct system

labelling, i nformation suppli ed within

documentation and also the way in which

thresholds f or frequency of leak testing.

• For systems with a charge below 3kg, the

changes to the leak checking regim e will not apply

until 2017. Currently, there is no requirem ent f or

regular leak testing of syst ems with a total charge

below 3kg.

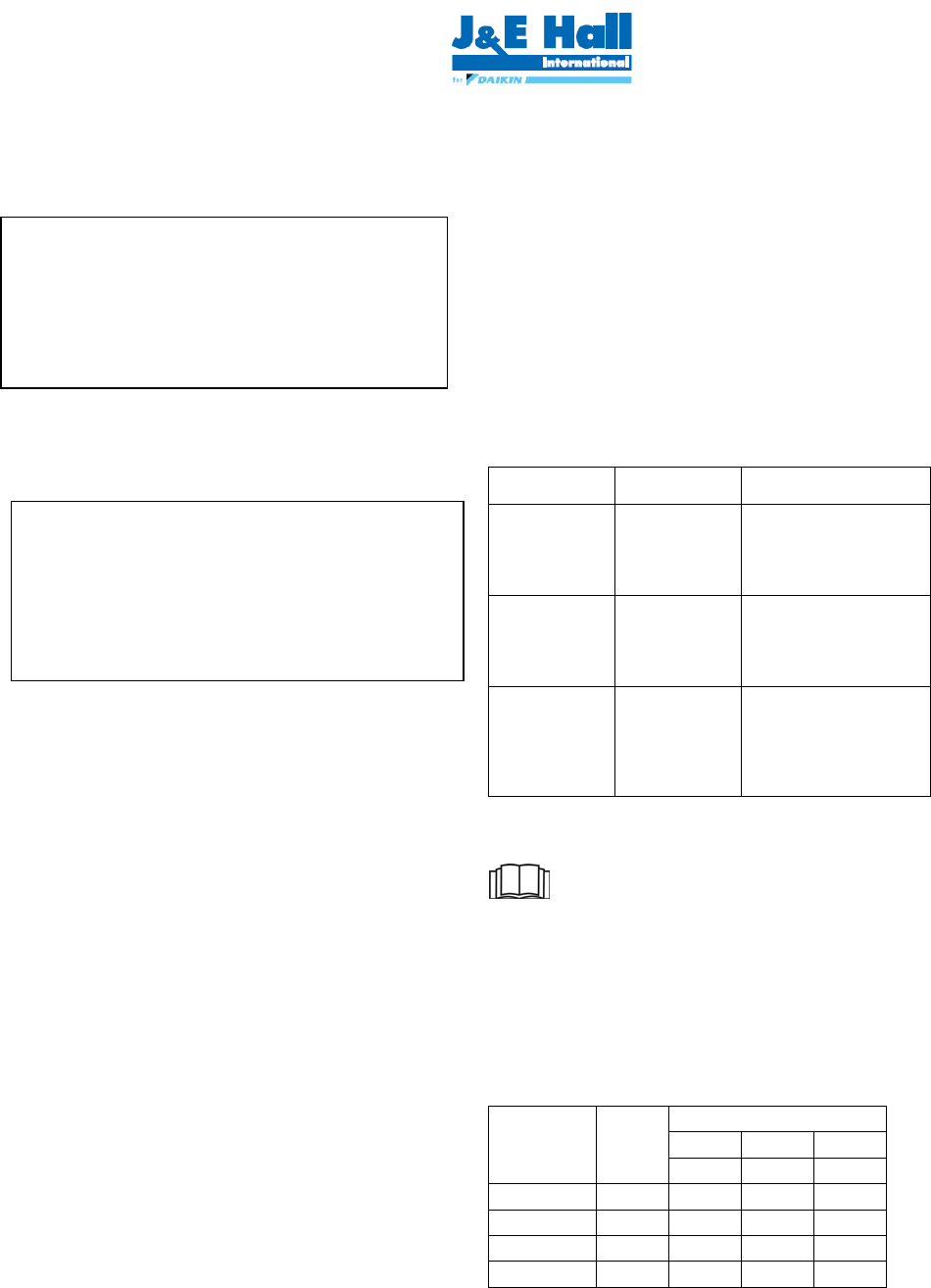

• Changes to leak testing requirements are as

follows:

OLD

LEGISLATION

NEW

LEGISLATION

LE AK CHECKING

FREQUENCY

3-30 kgs

5-50 TCO

2

Eq

Every 12 months but

can be increased to 24

months if fitted with a

fixed leak detecti on

system.

30-300 kgs

50-500

TCO

2

Eq

Every 6 months but can

be increased to 12

months if fitted with a

fixed leak detection

system.

300+ kgs

500+ TCO

2

Eq

Every 6 months -

however automatic leak

detection system is

mandatory which

requires servicing every

12 months.

Important i nformation regarding the refrigerant used

Its functioning rel i es on fluorinated greenhouse

gases

• This product is factory charged with N2.

• The refrigerant system will be charged with

fluorinated greenhouse gases. Do not vent gases

into the atmosphere.

The GWP (Global Warming Potential) values of refrigerants

which are specified for use in this equipm ent along with the

three new thresholds for leak testing requirements based on

TCO

2

Eq (Tonnes CO

2

Equivalent) are as follows:

Refrigerant

GWP

(1)

Refrigerant Charge - kg

5T

50T

500T

CO

2

Eq

CO

2

Eq

CO

2

Eq

R404A

3921.6

1.3

12.7

127

R407A

2107

2.4

23.7

237

R407F

1824.5

2.7

27.4

274

R134a

1430

3.5

35.0

350

Important No te

For scroll compressor: wiring for 3 phases must be

controlled. Supply phase sequence L1, L2 and L3 will affect

the rotating direction of scroll compressor and damage the

compressor.

Service technician should be present at initial start- up to

verify that the supply power is properly phased and that

compressor is rotati ng in the correct directi on.

Important No te

Warning! – Disconnect the mains electrical supply

before servicing or openi ng t he unit

Warning! – Ensure there is no refrigerant in refrigerant

circuit before dismantle it

Warning! – If the supply cord is damaged, it must be

replaced by the qualified service agent i n order to avoid

a hazard.

Ваш отзыв будет первым