- Тип техники

- Бренд

Просмотр инструкции автомойки Karcher CB 1 25, страница 26

26 English

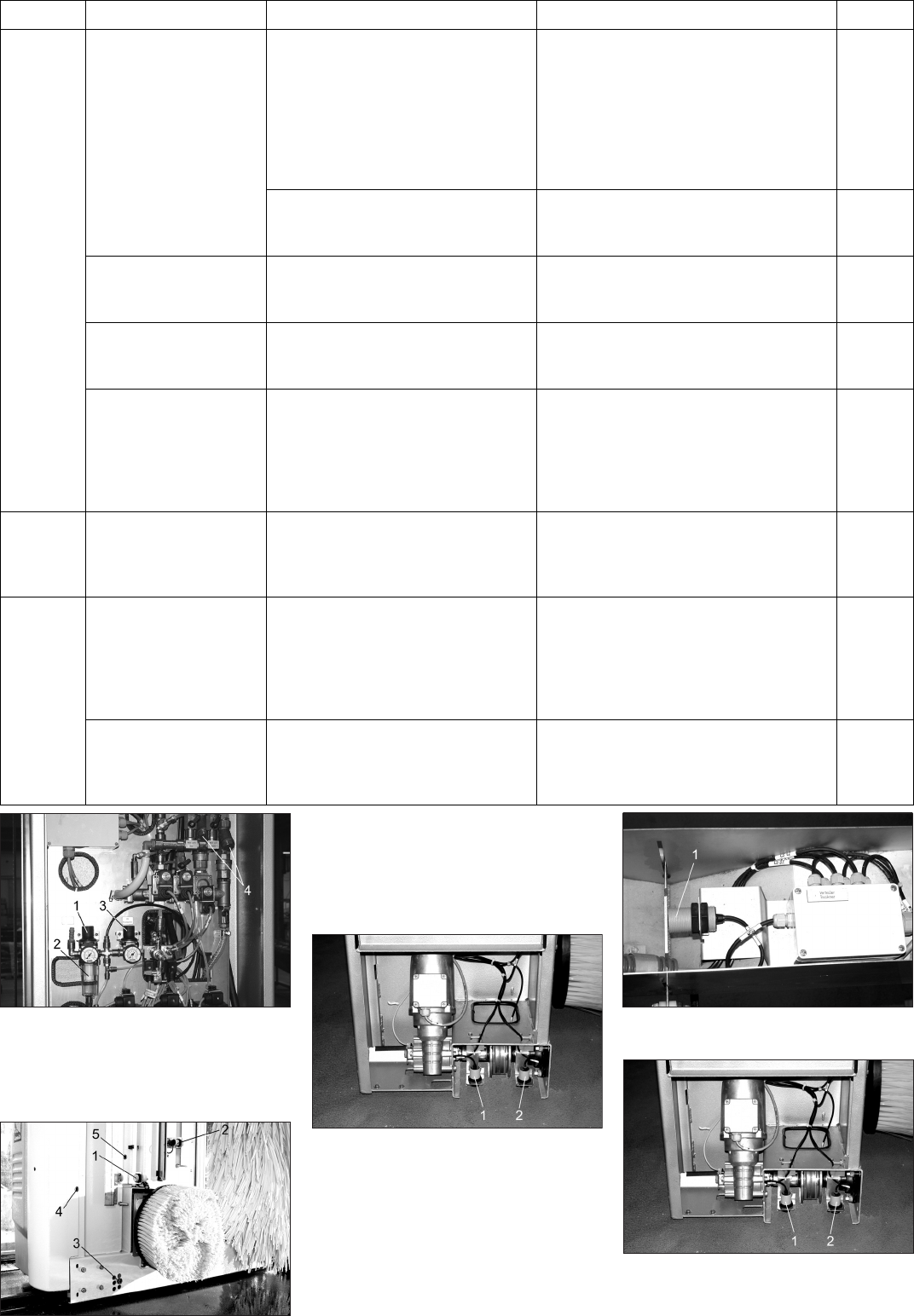

Figure 1

1 Maintenance unit

2Filter

3 Pressure lessener wheel wash

4 Dirt catcher

Figure 2

1 Lower roof brush limit switch (DBU)

2 Lower drier limit switch (TRU)

3 Light barrier wheel wash facility

4 Light barrier position 1

5 Light barrier position 2

Figure 3

1 Upper roof brush limit switch (DBO)

2 Upper roof drier limit switch (TRO)

Figure 4

1 Limit switch for roof drier safety bracket

Figure 5

1 Limit switch for travel start (PTS)

2 Limit switch for travel end (PFE)

Time Activity Assembly affected Remedy of whom

monthly or

after 2000

washes

Clean filter Block compressed air in the com-

pressed air maintenance unit (Diag. 1)

Turn off the compressed air supply and

use the manual operation to move the

wheel wash system in and out until the

pressure has been released. Then check

for zero pressure at the manometer, screw

off filter housing, remove filter cartridge,

clean filter with compressed air, re-insert

cartridge, and screw on housing.

Operator

Detergent suction filter in the deter-

gent containers

Screw off the cover of the detergent con-

tainers and rinse the filters of the suction

hoses with clean water.

Operator

Clean dirt catcher Dirt catcher Fresh water (option), Dirt

catcher Fresh water (Diag. 1)

Shut off water supply, screw off cover of

the dirt catcher, rinse out filter with water,

re-insert filter and screw on cover.

Operator

Visual check of belt for

roof brush, roof drier

Belt of roof brush, roof drier Visual inspection: Check status of the

belts, replace, if necessary (Customer

Service).

Custom-

er Serv-

ice

Tighten and and check

distance of all limit

switches

All limit switches (see diagrams 2 to 6) Check of the nominal distances of 4mm:

Use a 4mm thick flat material as feeler

gage, measure distance between limit

switch and switching flag. Readjust limit

switch, if necessary by shifting both plastic

nuts.

Custom-

er Serv-

ice

half-year-

ly or after

5000

washes

Check energy supply

line

Cables and hoses at: - energy column

or - energy chain or - cable tow

Visible inspection: Condition of hoses and

cables, leaks in hoses and connectors.

Check ease of movement of roller truck at

cable tow.

Operator

yearly or

after

10000

washes

Check plastic rollers and

rubber buffers

Running rollers (Diag. 7) and stop-

buffers of the side-brushes’ wagon,

stop-buffers of the side-brushes oscil-

late (Diag. 8)

Visual inspection: check state of the guide

rollers and play between rollers and guide

rails (maximum 5 mm play, binding of the

guide rollers at least 15 mm thick). Check

rubber buffers for cracks, visible inspec-

tion.

Operator

Check running surface SB traversing operation Check that running surface for SB travers-

ing operation is clean. Remove contamina-

tions using special cleaners (for e.g.6.869-

035).

Operator

Ваш отзыв будет первым