- Тип техники

- Бренд

Просмотр инструкции автомойки Karcher CB 1 25 Eco, страница 35

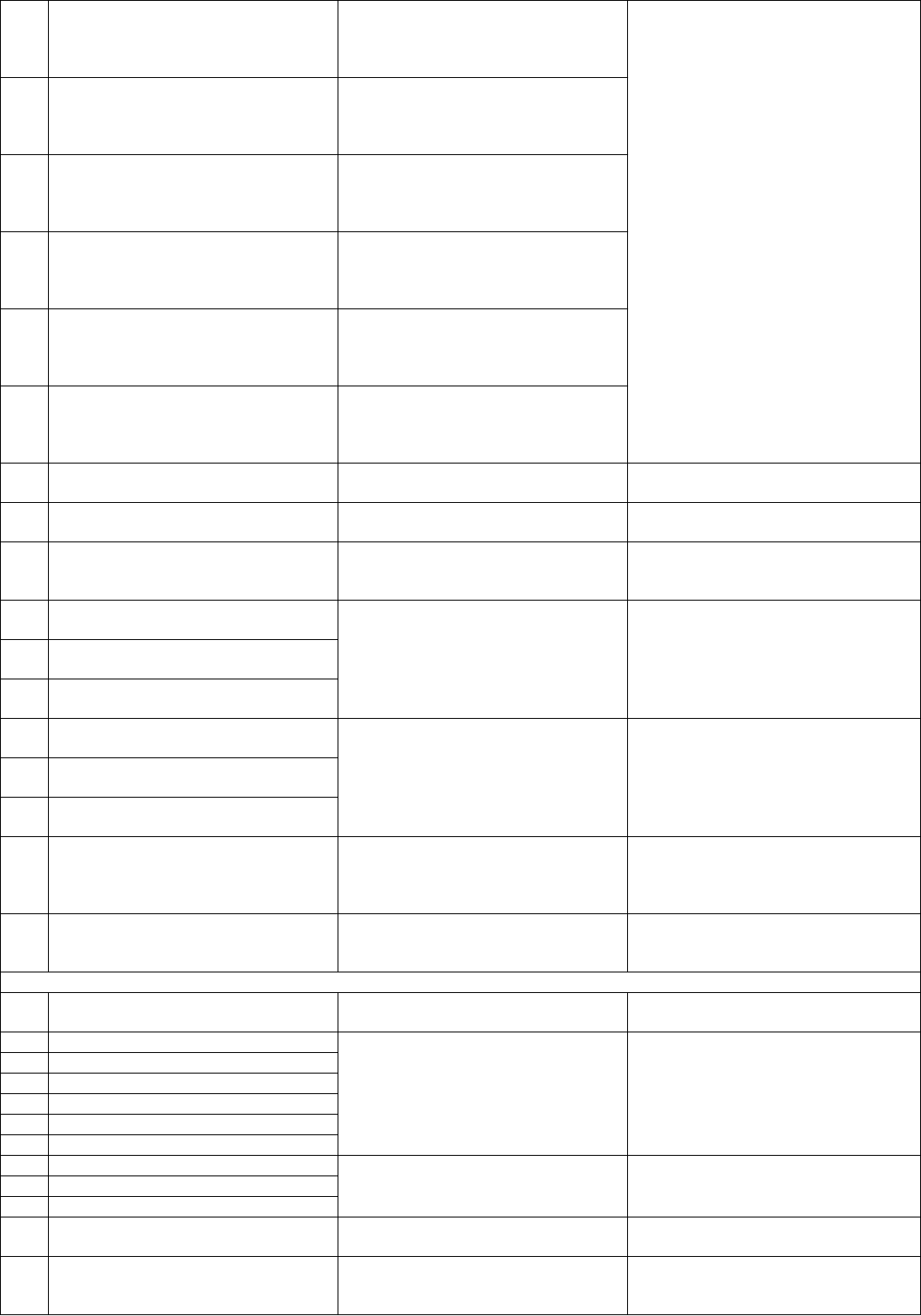

- 16

162 Pressure switch of high pressure pump

was triggered forward for roof nozzles

High pressure nozzles of roof blocked to-

wards the front or compressed air supply

to the portal has stopped or pressure

switch is defective

Clean the corresponding high pressure

nozzles, check compressed air supply, re-

peat washing process, call Customer

Service

163 Pressure switch of high pressure pump

was triggered backward for roof nozzles

High pressure nozzles of roof blocked to-

wards the rear or compressed air supply to

the portal has stopped or pressure switch

is defective

164 Pressure switch of high pressure pump

was triggered for side nozzles

High pressure nozzles of side pipes

blokked or compressed air supply to portal

has been switched off or pressure switch

is defective

165 Pressure switch of high pressure pump

was triggered for wheel cleaning

High pressure nozzles of wheel washing

blocked or compressed air supply to portal

has been switched off or pressure switch

is defective

166 Pressure switch of high pressure pump

was triggered for underbody cleaning

High pressure nozzles of underbody

cleaning blocked or compressed air sup-

ply to portal has been switched off or pres-

sure switch is defective

167 Pressure switch of high pressure pump

was triggered for floor cleaning

High pressure nozzles of floor cleaning

blocked or compressed air supply to portal

has been switched off or pressure switch

is defective

168* Pressure switch of high pressure pump

too high despite bypass switching

Compressed air supply to the portal has been

stopped or pressure switch is defective

Check compressed air supply, repeat

washing process, call Customer Service

172 Frost protection is active Frost proteciton is active Washing cannot be done until the anti-frost

temperature is exceeded again

175 Trailer coupling detected Side brush has got hooked into the trailer

coupling

No action is required; washing will contin-

ue automatically without the back being

washed a second time

180 CAN bus error, module A8, no connection

(in main switching cabinet CB2)

Loose connecting chord of the plates,

plates defective

Switch off and switch on the unit, repeat

washing process, call Customer Service

181 CAN bus error, module A9, no connection

(high pressure distributor to portal)

185 CAN bus error, module A29, no connec-

tion (pump switching cabinet)

190 Excess current outlets CAN Bus module

A8 (in main switching cabinet CB2)

Short circuit, water leakage Switch off and switch on the unit, repeat

washing process, call Customer Service

191 Excess current outlets CAN Bus module

A9 (high pressure distributor to portal)

195 Excess current outlets CAN Bus module

A29 (pump switching cabinet)

200 Control voltage is missing Emergency stop pressed, protective

switch triggered, reset button has not been

pressed

Press all emergency stops, check that all

protective motor switches have been

switched on, press reset button in the con-

trol station

201 Plant not in operation (operational time

switched off)

Night switch off of the unit is active, key

switch of the feed distributor is positioned

at "0"

Check key switch of the feed distributor

(position it to 1 or 2)

* green indicator lamp at the switching cabinet goes off.

Dis-

play

Fault Possible cause Remedy

203 Portal not in normal setting Unit not in normal setting Drive unit to normal setting

204 Side-brushes not facing outwards

205 Side-brush 1 not facing outwards

206 Side-brush 2 not facing outwards

208 Roof brush not facing upward

209 Drier not facing upward

210 Wheel washing not facing outward Unit not in normal setting or compressed

air supply has been switched off

Check compressed air supply; drive unit

into normal setting

211 Wheel washing 1 not facing outwards

212 Wheel washing 2 not facing outwards

250 Unit has not been initialised Measurement drive has not yet been done Washing is not possible; call Customer

Service

251 Emergency operations of processed water

are active

Processed water unit has a fault Repair processed water plant; unit an be

used with fresh water in emergency opera-

tions mode

35EN

Ваш отзыв будет первым