- Тип техники

- Бренд

Просмотр инструкции автомойки Karcher CB 1 23, страница 25

English 25

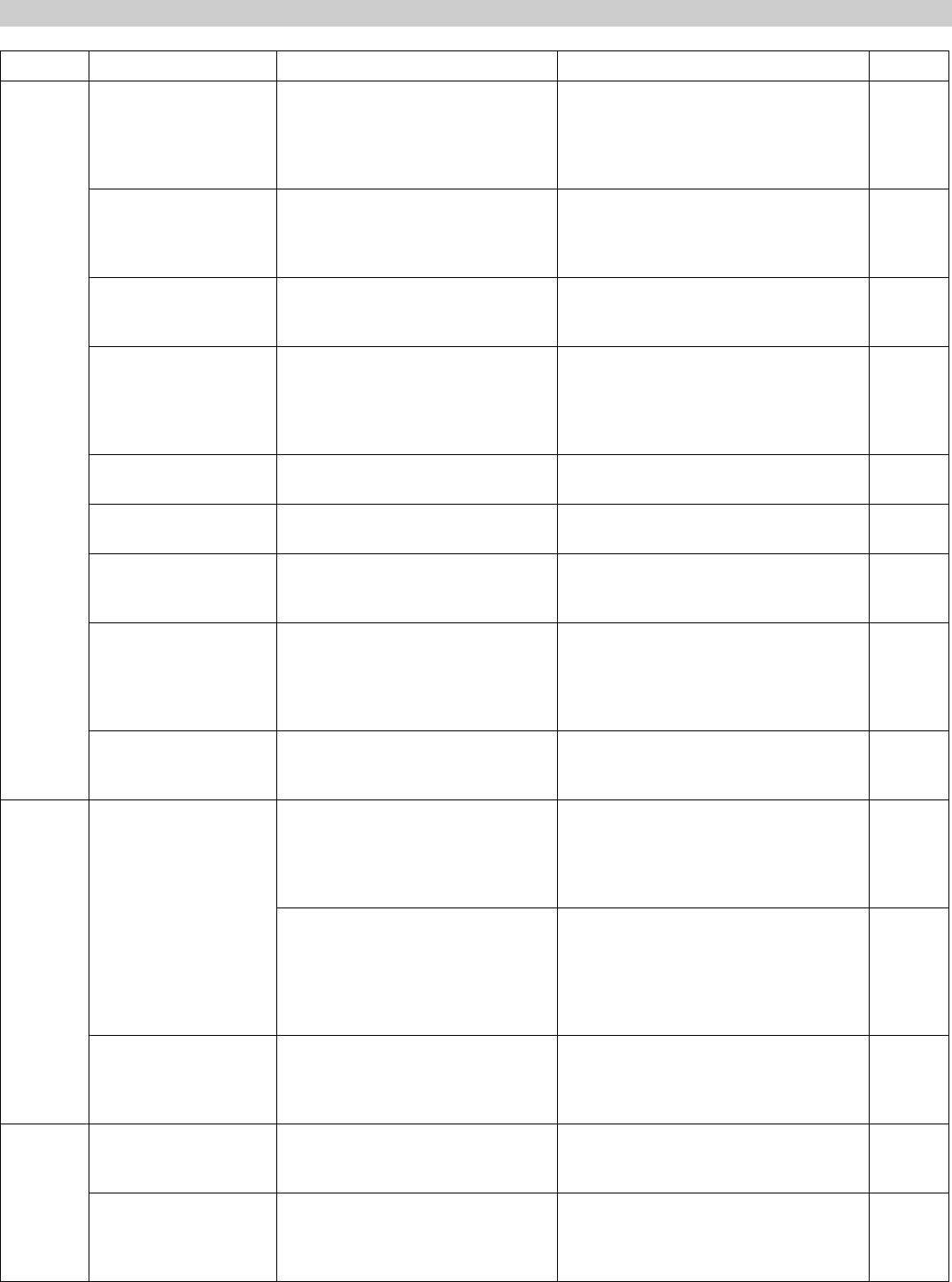

Maintenance schedule

Time Activity Assembly affected Remedy of whom

daily Check safety installa-

tions

Emergency-stop button on operating

point for manual mode, wash card/

code reader, all other emergency-stop

buttons in the plant, safety switches in

the small halls.

Start wash programme, activate emergen-

cy-stop buttons or safety switches. The

plant must stop, then press the control sup-

ply voltage/normal position button on the

operating point for manual mode.

Operator

Check notes for self-op-

eration customers (only

with self-operation

plants).

Signs with operation instructions and

proper use according to the stipula-

tions to be placed at the wash place.

Check signs for completeness and legibili-

ty. Replace damaged signs.

Operator

Check filling level of the

detergent.

The detergent container is located in

the column on the right when facing

the direction of travel

If necessary, fill up. Operator

Check spray jets for

blockage

Jets in the upper section, jet pipes on

the columns and the underfloor wash

plant (option), also high-pressure jets

(option)

Make visible inspection (judge spray pic-

ture), if necessary, clean. Warning! Do not

mix up jets! Screw off jets individually,

clean with compressed air, screw on

again.

Operator

Clean light barriers. All light barriers (diagrams 2 und 9) Applying gentle pressure, wipe light barri-

ers with a detergent-free soft, damp cloth.

Operator

Visual inspection All limit switches (see diagrams 3 to 6) Check for mechanical damage and stable

seating.

Operator

Check brush rollers for

foreign bodies

Side-brushes, roof brush, wheel

brushes

Make visible inspection, remove possible

foreign bodies that are present, clean

soiled brushes with high-pressure cleaner.

Operator

Check water supply Rinse and spray circulation Shut off water in manual operation and

check whether enough water is present in

the vehicle wash. Too little or no water may

cause damage to the vehicle being

washed.

Operator

Function test Positioning ramp Interrupt light barriers "position 1“ and "po-

sition 2“ (see Fig. 2). The positioning ramp

must indicate corresponding signal.

Operator

weekly or

after 500

washes

Check condition of the

washing brushes.

Roof brush roll and side brush rolls Check brush shaft for straightness, check

brush segments on firm seating, check

brush for wear (minimum bristle length:

new state minus 50 mm) if necessary, re-

place.

Operator

Wheel washing brushes Replace brushes after approx. 10000

washing processes. For this: loosen 3

screws within the bristle ring, remove

wheel washing brush, attach new wheel

washing brush and fasten it with the 3

screws.

Opera-

tor/Cus-

tomer

Service

Check hoses and piping

for absence of leakness.

Hoses of the supply line and in the

portal

Visual inspection Opera-

tor/Cus-

tomer

Service

after 1000

washes

Visual inspection Running rollers of the side-brushes’

wagon (Diag. 7)

Check play by moving the side-brushes.

Inform Customer Service when there is too

much play between roller truck and guide:

Operator

Reset Screws for guide rails (roof brush, roof

drier)

Check using a hexagon socket wrench that

screws are firmly screwed in, tighten if nec-

essary (apply approx. 25 Nm tightening

torque)

Opera-

tor/Cus-

tomer

Service

Ваш отзыв будет первым