- Тип техники

- Бренд

Просмотр инструкции сварочного оборудования Telwin TECHNOMIG 225 PULSE, страница 6

- 6 -

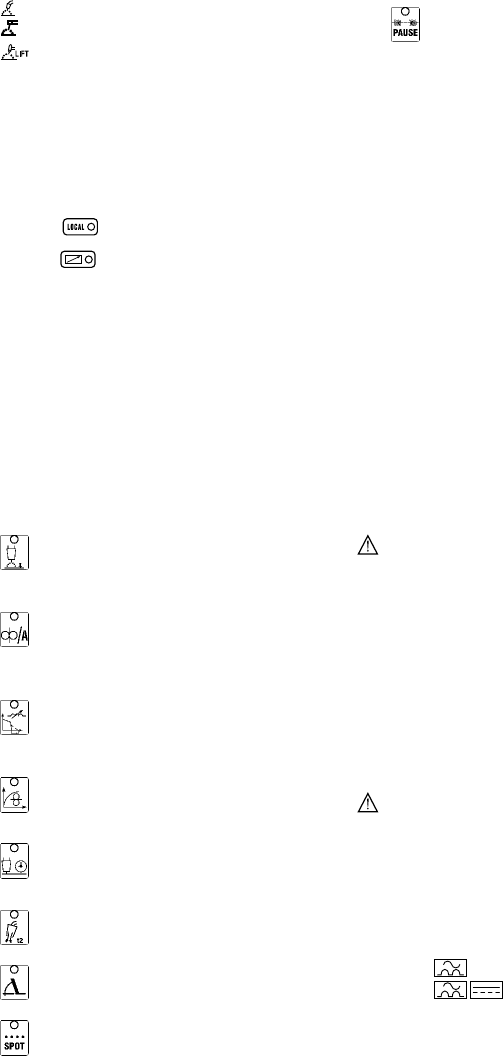

- : MIG/MAG/FLUX in SHORT/SPRAY ARC.

- : MMA electrode.

14i- parameter 9: Pause time in MIG/MAG/FLUX spot-

welding regulates the duration of the pause between one spot-

- : TIG-DC with LIFT strike.

weld and the next. When the setting is 0 sec, in order to carry out

9- Key for selecting welding process.

the next spot-weld it is necessary to release the torch button and

When the machine is in MIG/MAG/FLUX mode it is possible to

then press it again.

choose between 2-stroke and 4-stroke control or with spot-

welding timer ( SPOT).

STORING AND RECALLING CUSTOMISED MIG/MAG

10- Key for selecting type of material.

PROGRAMS

Sets the operating mode according to the material or the

Introduction

procedure.

The welding machine can be used to (STORE) customised work

Only active if in synergy (13).

programs relating to a set of valid parameters for a particular welding

11- Key for selecting wire diameter is used for setting wire

job. Each stored program can be recalled (LOAD) at any time so that

diameter. For a diameter of 1.2mm it is necessary to press the

the user finds the welding machine “ready-to-use” for a specific job that

button until both LED's corresponding to diameters of 0.6 and

has been optimised previously. It is possible to store 9 customised

0.8mm light up.

programmes in the welding machine.

Only active if in synergy (13).

12- Key for selecting remote control.

Storage procedure (STORE)

After adjusting the welding machine for optimal operation with a given

- When LED is on, the controls on the welding machine

type of weld proceed as follows (FIG.C):

panel are enabled.

a) Press button (7) “STORE” for 3 seconds.

b) “St_ ”will appear on the display (4) with a number between 1 and 9.

- When LED is on, adjustments can only be carried out by

c) Turn the knob (5) to choose the desired programme number for

the remote control:

storage.

a) single potentiometer control: replaces encoder operation

d) Press key (7) again “STORE”:

(5).

- if the STORE key is pressed for more than 3 seconds, the

b) control with two potentiometers: replaces encoder

program has been stored correctly. “YES” appears on the display;

operation (5) and the auxiliary parameter function.

- if the STORE key is pressed for less than 3 seconds, the program

c) pedal remote control: replaces encoder operation (5) in TIG

has not been stored. “ no” appears on the display.

mode.

13- Key for selecting synergy welding. To set synergy operation of

Loading procedure (LOAD)

the machine in MIG/MAG welding it is necessary to press the

Proceed as follows (see FIG.C):

button.

a) Press button (6) “LOAD” for 3 seconds.

WARNING! Even though the machine allows you to set every

b) “Ld_ ”will appear on the display (4) with a number between 1 and 9.

welding parameter freely, there are particular parameter

c) Turn the knob (5) to choose the number used to store the

combinations that may have no meaning from the electrical or

programme that is now to be used.

welding point of view. The welding machine will not break down

d) Press key (6) “LOAD” again:

however, but it may not operate according to the incorrect setting.

- if the LOAD key is pressed for more than 3 seconds, the program

14- Key for selecting welding parameters.

has been loaded correctly. “YES” appears on the display;

Pressing the key repeatedly will light up one of the LED's from

- if the LOAD key is pressed for less than 3 seconds, the program

(14a) to (14i) associated with a specific parameter. The setting for

has not been loaded. “ no” appears on the display.

the value of each activated parameter is made using the

ENCODER (5) and is shown on the display (4).

NOTE: during operations with the “store” and “load” keys the prg.

Note: Parameters that cannot be modified by the operator,

depending on whether you are working with a synergy programme

5. INSTALLATION

or in manual mode, are automatically excluded from the selection;

the corresponding LED will not light up.

______________________________________________________

WARNING! CARRY OUT ALL INSTALLATION OPERATIONS

AND ELECTRICAL CONNECTIONS WITH THE WELDING

14a- parameter 1: Selects the welding voltage. In

MACHINE COMPLETELY SWITCHED OFF AND DISCONNECTED

MIG/MAG/FLUX it regulates the welding voltage in Volts or the

FROM THE POWER SUPPLY OUTLET.

arc correction in synergy (only for MIG/MAG).

THE ELECTRICAL CONNECTIONS MUST BE MADE ONLY AND

During welding it displays the power source output voltage.

EXCLUSIVELY BY AUTHORISED OR QUALIFIED PERSONNEL.

______________________________________________________

Assembling the protective mask

14b- parameter 2: Sets the wire feed rate or welding

Fig. D

current. In

MIG/MAG/FLUX it is the wire feed rate in metres per minute. In

Assembling the return cable-clamp

MMA it is the welding current in amps. During welding it displays

Fig. E

the power source output current.

Assembling the welding cable-electrode holder clamp

Fig. F

14c- parameter 3: Arc force or Electronic reactance. In

Locate the welding machine in an area where openings for cooling air

MMA it is arc force or arc penetration regulation. In

are not obstructed (forced circulation with fan), leave at least 250mm

MIG/MAG/FLUX it has a similar meaning but is called electronic

free space around the welding machine; check that conductive dusts,

reactance.

corrosive vapours, humidity etc., will not enter welding machine.

______________________________________________________

14d- parameter 4: Acceleration slope-up: In

WARNING: Position the welding machine on a flat surface

with sufficient carrying capacity for the weight of the welding

MIG/MAG/FLUX it regulates the gradient of the acceleration

machine, to prevent tipping or hazardous movement.

slope-up of the wire feeder moter.

______________________________________________________

CONNECTION TO THE MAIN POWER SUPPLY

14e- parameter 5: Burn-back time in MIG/MAG/FLUX it

Warning

- Before making any electrical connection, make sure the rating data

regulates the time interval elapsing between when the wire

of the welding machine correspond to the mains voltage and

stops and the output current falls to zero.

frequency available at the place of installation..

- The welding machine should only be connected to a power supply

system with the neutral conductor connected to earth.

14f- parameter 6: Postgas. in MIG/MAG/FLUX it regulates

the postgas time in seconds.

14g- parameter 7: Slope-down. In MIG/MAG it is the slope-

- To comply with the requirements of the EN 61000-3-11 (Flicker)

down time (only in synergy (13)).

standard we recommend connecting the welding machine to

interface points of the power supply that have an impedance of less

than Zmax =0.18 ohm.

14h- parameter 8: Spot time. In MIG/MAG/FLUX it regulates

PLUG AND OUTLET

the welding current duration in SPOT-welding.

Connect a normalised plug (2P + T) having sufficient capacity- to the

power cable and prepare a mains outlet fitted with fuses or an

- To ensure protection against indirect contact use residual current

devices of the following types:

- Type A ( ) for single phase machines;

- Type B ( ) for 3-phase machines.

Ваш отзыв будет первым