- Тип техники

- Бренд

Просмотр инструкции котла Ferroli ATLAS D K100, страница 11

ATLAS D 30 K 100

26

EN

cod. 3540S361 - 08/2009 (Rev. 00)

4. SERVICE AND MAINTENANCE

All adjustment, conversion, commissioning and maintenance operations described be-

low must only be carried out by Qualified Personnel (meeting the professional technical

requirements prescribed by current regulations) such as those of the Local After-Sales

Technical Service.

FERROLI declines any liability for damage and/or injury caused by unqualified and un-

authorised persons tampering with the unit.

4.1 Adjustments

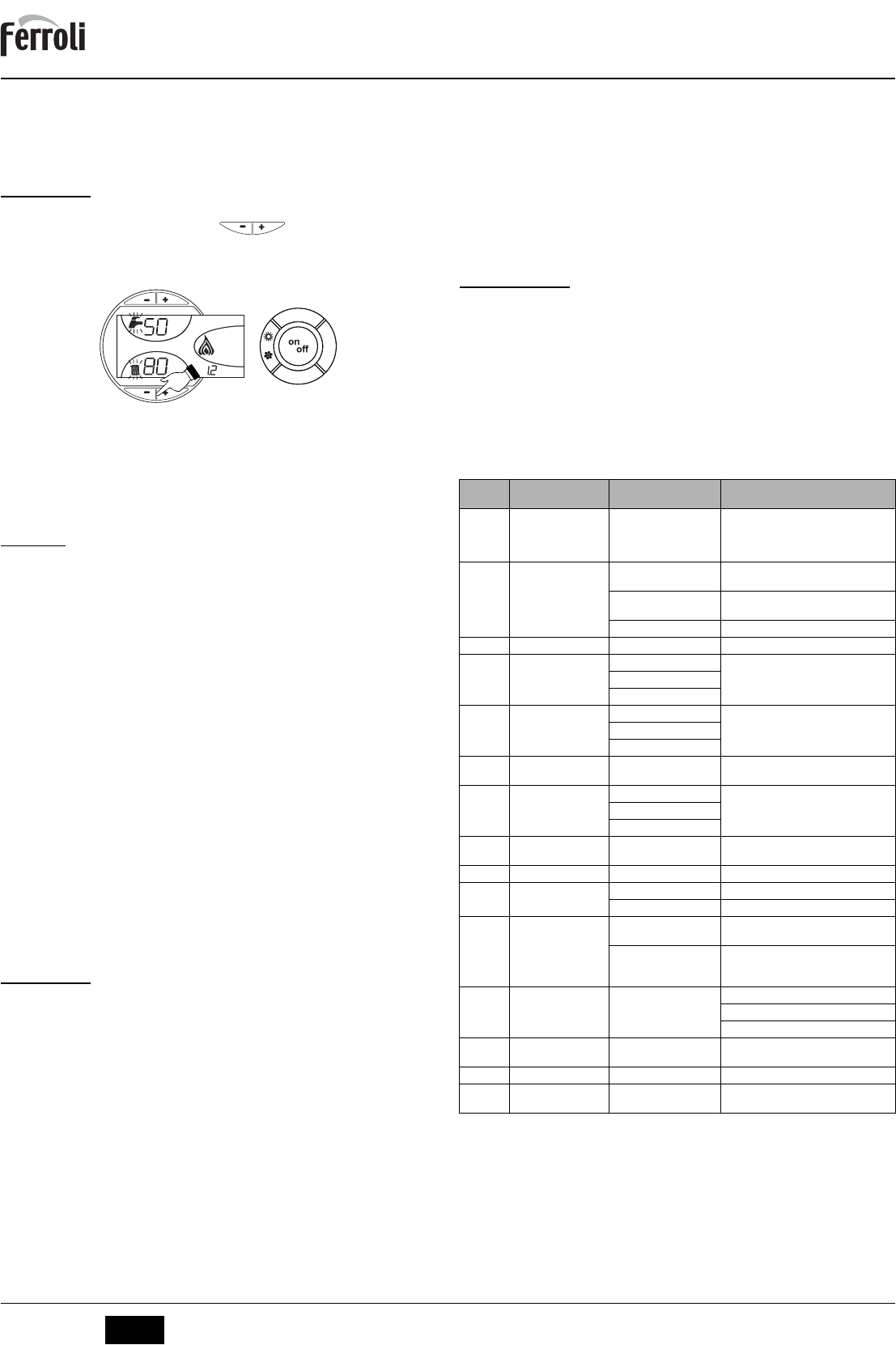

TEST mode activation

Press the heating buttons (details 3 and 4 - ) together for 5 seconds to ac-

tivate the fig. 1TEST mode. The boiler lights at maximum power.

The heating symbol (detail 24 - fig. 1) and DHW symbol (detail 12 - fig. 1) flash on the

display.

fig. 17 - TEST mode

To deactivate the TEST mode, repeat the activation sequence.

The TEST mode is automatically disabled in any case after 15 minutes.

Burner adjustment

Boiler efficiency and correct operation depend above all on accurate burner adjustments.

Carefully follow the Manufacturer's instructions. The two-stage burners must have the

first stage adjusted to a power level not below the boiler's rated min. power. The power

of the second stage must not be higher than the boiler's rated max. power.

4.2 Start-up

B

Checks to be made at first lighting, and after all maintenance operations that

involved disconnecting from the systems or an intervention on safety devices

or parts of the boiler:

Before lighting the boiler

• Open any on-off valves between the boiler and the systems.

• Check the seal of the fuel system.

• Check correct prefilling of the expansion tank.

• Fill the water system and make sure that all air contained in the boiler and the sys-

tem has been vented, by opening the air valve on the boiler and any air valves on

the system.

• Make sure there are no water leaks in the system, domestic hot water circuits, con-

nections or boiler.

• Check correct connection of the electrical system and efficiency of the earthing sys-

tem

• Make sure there are no flammable liquids or materials in the immediate vicinity of

the boiler

Checks during operation

• Turn the unit on as described in sec. 2.3.

• Check the seal of the fuel circuit and water systems.

• Check the efficiency of the flue and air-fume ducts during boiler operation.

• Make sure the water is circulating properly between the boiler and systems.

• Check correct boiler lighting by performing various tests, turning it on and off with

the room thermostat or remote control.

• Make sure the fuel consumption indicated on the meter matches that given in the

technical data table on sec. 5.3.

• Ensure the seal of the fumebox and burner door.

• Make sure the burner works properly. This check must be made with the special in-

struments, following the manufacturer's instructions.

• Check correct programming of the parameters and carry out any required customi-

sation (compensation curve, power, temperatures, etc.).

4.3 Maintenance

Periodical check

To ensure correct operation of the unit over time, have qualified personnel carry out a

yearly check, providing for the following:

• The control and safety devices must function correctly.

• The fume exhaust circuit must be perfectly efficient.

• Check there are no obstructions or dents in the fuel supply and return pipes.

• Clean the filter of the fuel suction line.

• Measure the correct fuel consumption

• Clean the combustion head in the fuel outlet zone, on the swirl disc.

• Leave the burner running at full rate for approximately ten minutes, then analyse

the combustion, checking:

- All the elements specified in this manual are set correctly

- Temperatures of the fumes at the flue

- CO2 percentage content

• The air-fume end piece and ducts must be free of obstructions and leaks

• The burner and exchanger must be clean and free of deposits. For possible clean-

ing do not use chemical products or wire brushes.

• The gas and water systems must be airtight.

• The water pressure in the cold water system must be approx. 1 bar; otherwise, bring

it to that value.

• The circulating pump must not be blocked.

• The expansion tank must be filled.

• Check the magnesium anode and replace it if necessary.

A

The boiler casing, control panel and aesthetic parts can be cleaned with a soft

and damp cloth, if necessary soaked in soapy water. Do not use any abrasive

detergents and solvents.

Boiler cleaning

1. Disconnect the power supply to the boiler.

2. Remove the front top and bottom panel.

3. Open the door by undoing the knobs.

4. Clean the inside of the boiler and the entire path of exhaust fumes, using a tube

brush or compressed air.

5. Then close the door, securing it with the knob.

To clean the burner, refer to the Manufacturer's instructions.

4.4 Troubleshooting

Diagnostics

The boiler is equipped with an advanced self-diagnosis system. In case of a boiler fault,

the display will flash together with the fault symbol (detail 22 - fig. 1) indicating the fault

code.

Some faults cause permanent shutdown (marked with the letter "A"): to restore opera-

tion, press the RESET button (detail 8 - fig. 1) for 1 second or RESET on the optional

remote timer control if installed; if the boiler fails to restart, it is necessary to eliminate the

fault indicated by the operation LED's.

other faults (indicated with the letter "F") cause temporary shutdowns which are automat-

ically reset as soon as the value returns within the boiler's normal operation range.

Table. 2 - List of faults

e

c

o

c

o

m

f

o

r

t

m

o

d

e

r

e

s

e

t

eco

bar

Fault

code

Fault Possible cause Cure

A01

Burner block

(RESET ONLY

OCCURS ON THE

BURNER)

Refer to the burner manual

A03

Overtemperature protec-

tion activation

Heating sensor damaged

Check the correct positioning and operation

of the heating sensor

No water circulation in the

system

Check the circulating pump

Air in the system Vent the system

F07

Wiring fault Connector X5 not connected Check the wiring

F10

Delivery sensor 1 fault

Sensor damaged

Check the wiring or replace the sensorWiring shorted

Wiring disconnected

F11

DHW sensor fault

Sensor damaged

Check the wiring or replace the sensorWiring shorted

Wiring disconnected

F13

Wiring fault

Connector X12 not con-

nected

Check the wiring

F14

Delivery sensor 2 fault

Sensor damaged

Check the wiring or replace the sensorWiring shorted

Wiring disconnected

F34

Supply voltage under

170V.

Electric mains trouble Check the electrical system

F35

Faulty mains frequency Electric mains trouble Check the electrical system

F37

Incorrect system water

pressure

Pressure too low Fill the system

Sensor damaged Check the sensor

F39

External probe fault

Probe damaged or wiring

shorted

Check the wiring or replace the sensor

Sensor disconnected after

activating the sliding tem-

perature

Reconnect the external probe or disable the

sliding temperature

F40

Incorrect system water

pressure

Pressure too high

Check the system

Check the safety valve

Check the expansion tank

A41

Sensor positioning

Delivery sensor not inserted

in boiler shell

Check the correct positioning and operation

of the heating sensor

F42

Heating sensor fault Sensor damaged Replace the sensor

F47

System water pressure

sensor fault

Wiring disconnected Check the wiring

Ваш отзыв будет первым