- Тип техники

- Бренд

Просмотр инструкции сварочного оборудования Fubag IR 220, страница 10

www.fubag.ru

Omperator's anual

- 9 -

9. Troubleshooting

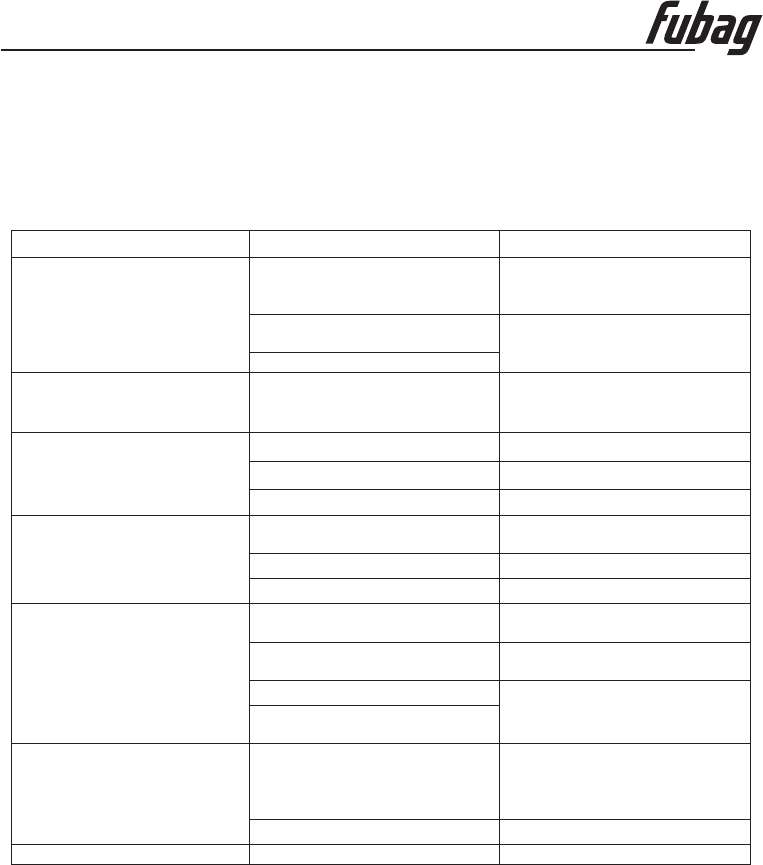

Breakdown Analysis Solutions

Bad power ventilation lead to

over-heat protection

Improve the ventilation

condition.

Circumstance temperature is

too high

Yellow Indicator is on

Using over the rated duty-cycle

It will automatically recover

when the

Temperature low down

The adjustment knob on the

front panel didn’t work

Potentiometer broken (current

regulation)

Replace the potentiometer.

Switch broken Replace the switch

Fan broken Replace or repair the fan

Cooling Fan not working or

turning very slowly

Wire broken or falling off Check the connection

Over voltage, under voltage or

scarcity of phase

See No. 1

Welder getting overheated See No. 1

No no-load voltage

Switch broken Replace the switch

Electrode Holder’s capacity is

too small;

Replace it with a bigger

capacity one

Cable is of small size

Replace it with another one in

conformity with the requirement

Socket loosen

Electrode Holder and Cable

getting

hot;“+” “-” polar sockets

becoming hot

Bigger resistance between the

electrode holder and the cable

Remove the oxide skin and

tighten it

Resume power over a long

period of time ( more than two

days )

Not failure. Trip caused by the

main power filter’s capacity

charging. Switch 6 on the main

power source.

Power source tripping

In the process of welding Contact us

Others Contact us

Ваш отзыв будет первым