- Тип техники

- Бренд

Просмотр инструкции сварочного оборудования Fubag INMIG 160, страница 9

www.fubag.ru

Omperator's anual

--8

- Lead wire into “Wire Guide Pipe” of wire feeder, align wire with roll groove through “Drive Roll”, re-

lead “Socket Tip” and press “Drive Roll”. (If more welding wire is needed, it will be done after

switching on the power.)

- Insert the connector of torch into “Torch Access Hole” on the front panel of the welder and rotate

the screw cap firmly.

Connect the copper tip of the earth clamp which thread through the wire access hole on the panel

with “-“ of the “connecting tip”. The connecting cable must be reliable, or the connecting tip will burn

out.

In order to reach sound performance when welding with flux-cord wire, it’s available that connect

the “+”, “-” in an opposite way, that’s the wire feed motor with “-“and the connecting cable with “+”.

Do not use steel plate or the materials alike which are ill conductor to connect between

welder and work piece.

a) Connection of welder and welding cable

Connect the quick connector of welding cable to the output on front panel, and deasil turn down.

The electrode holder is used for clamp the electrode

b) Connection of welder and grounding cable

Connect the quick connector of grounding cable to the output on the front panel, and deasil turn

down. The earth clamp is used for clamp the work piece

Do not use steel plate or the materials alike which are ill conductor to connect between

welder and work piece.

-

-

.

.

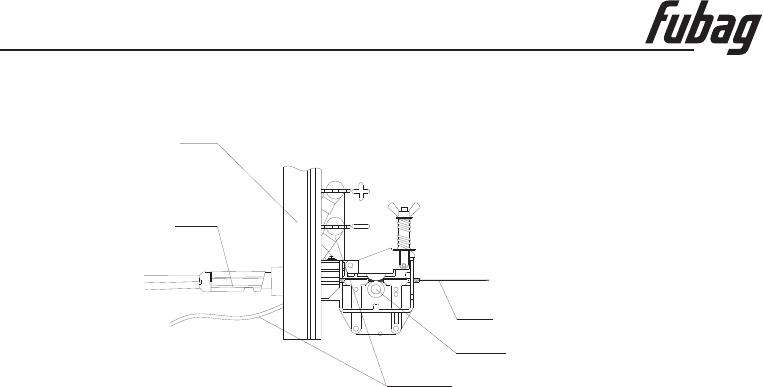

Connection between Welder and Torch

Connection of the Connection Cable

The Connection and installation of stick welding

Notice:

Notice:

FRONT

PANEL

TORCH

WIRE

EARTH CABLE

FEED ROLLER

Ваш отзыв будет первым