- Тип техники

- Бренд

Просмотр инструкции снегоходы Ski Doo SUMMIT 2005, страница 994

Section 03 ENGINES (2-STROKE)

Subsection 04 (LEAK TEST AND ENGINE DIMENSION MEASUREMENT)

Lay part on a surface plate (marble, mirror or thick

glass plate).

Holding down one end of part, try pushing down

the other end.

If any play is felt, part must be rectified.

RECTIFYING SURFACES

Stick a fine sand paper sheet on the surface plate

then lightly oil the sand paper.

Rub part mating surface on sand paper using 8-fig-

ure movements.

Sand until mating surface is perfectly straight.

A00A1LA

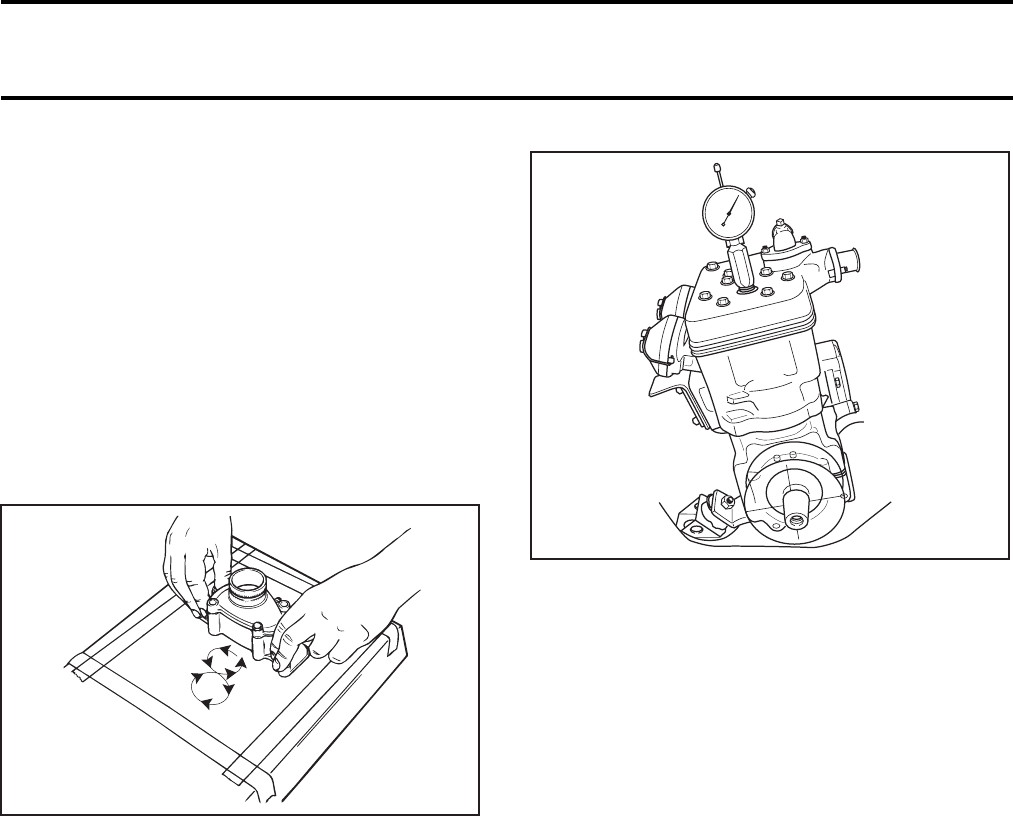

CHECKING CRANKSHAFT

ALIGNMENT

Install a degree wheel (P/N 414 352 900) on crank-

shaft end.

Remove both spark plugs.

Install a dial indicator (P/N 414 104 700) in spark

plug hole on MAG side.

Bring MAG piston at top dead center.

Rotate degree wheel (P/N 414 352 900) (not

crankshaft) so that 360° mark aligns with center

of crankcase. Scribe a mark on crankcase.

Remove dial indicator (P/N 414 104 700) and install

it on PTO side cylinder.

Bring PTO piston to top dead center. degree

wheel (P/N 414 352 900) must rotate with crank-

shaft.

0

90

80

70

60

50

40

30

20

10

1

8

0

0

A06C1TA

TYPICAL

Interval between cylinders must be 180° ±0.5.

Any other reading indicates a misaligned (twisted)

crankshaft.

mmr2005-013 121

Ваш отзыв будет первым