- Тип техники

- Бренд

Просмотр инструкции снегоходы Ski Doo SUMMIT 2005, страница 747

Section 06 DRIVE SYSTEM

Subsection 06 (CHAINCASE)

CHAINCASE HOUSING

BEARINGS

Inspection

The bearings must turn smoothly and freely. If

not, replace them.

Removal

To remove the upper bearing no. 28, remove the

circlip no. 32 and pull the bearing out of the hous-

ing. The bearing is not installed press fit in the

housing.

For the lower bearing no. 29 a press machine will

be necessary.

Remove the circlip no. 33. Turn the housing and

remove the oil seal no. 31.

Support the housing around bearing location and

push the bearing out of housing with the press.

Installation

The installation is the reverse of the removal pro-

cedure.

NOTE: Always install bearings with their seals to-

wards inside of chaincase.

A35D0NA

COUNTERSHAFT

Removal

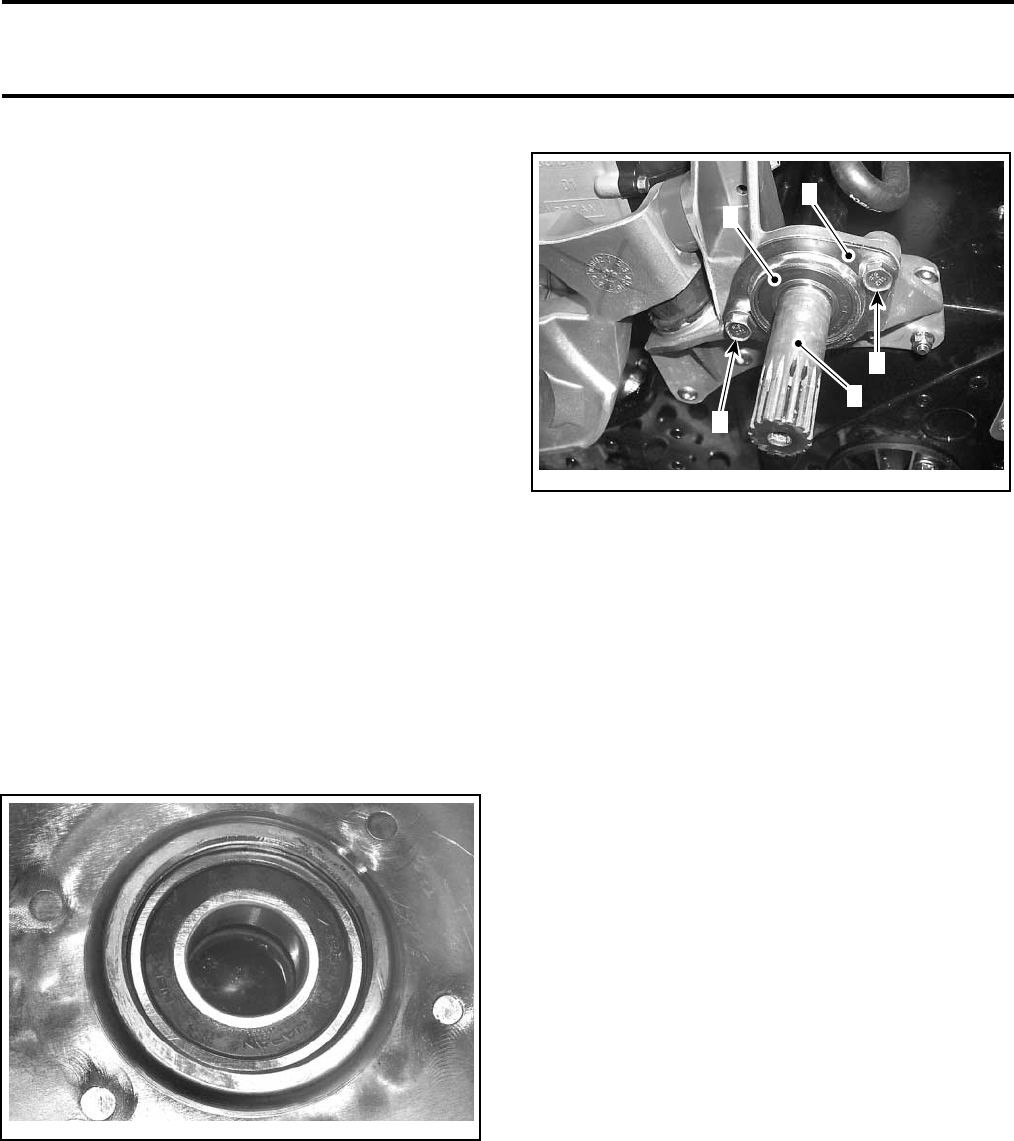

On Left Side of Vehicle:

Remove driven pulley and its shims, refer to DRIV-

EN PULLEY.

Unscrew the bearing flange bolts no. 34 and re-

move the bearing flange no. 35.

A35D0OA

4

1

2

3

2

1. Bearing flange

2. Bearing flange bolts

3. Countershaft

4. Countershaft bearing

On the Right Side of Vehicle:

Remove:

– drive chain and sprockets

– spacer no. 24.

Using a plastic hammer, knock on the countershaft

no. 25 until the countershaft bearing comes out of

its support.

Remove countershaft.

To remove the countershaft bearing no. 36,see

COUNTERSHAFT BEARING further in this sec-

tion.

Inspection

Check countershaft for wear, bend or cracks.

Check splines for wear or damages.

Replace countershaft if any damage is detected.

Installation

The installation is the reverse of the removal pro-

cedure.

NOTE: If a new countershaft is installed, perform

bearing shimming procedure. Refer to COUN-

TERSHAFT BEARING.

COUNTERSHAFT BEARING

Inspection

No play must be felt between countershaft bear-

ing no. 36 and countershaft no. 25.

mmr2005-136 229

Ваш отзыв будет первым